Basic Info

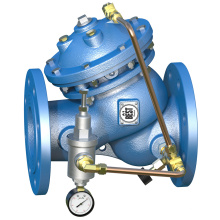

Model No.: FLV08

Click on the follow link to find out more information: https://www.aone-best.com/y-type-float-valve/

Company Info

- Company Name: A1BEST International Corporation

- Representative: CHANG YUAN CHIEH

- Product/Service: VALVES , BUTTERFLY VALVE , GLOBE VALVE , FLAT VALVE , STATION VALVE , HYDRAULIC CONTROL VALVE

- Capital (Million US $): US $ 25,000,000

- Year Established: 2017

- Total Annual Sales Volume (Million US $): US$50 Million - US$100 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): US$50 Million - US$100 Million

- No. of Production Lines: Above 20

- No. of R&D Staff: 21 -30 People

- No. of QC Staff: 31 -40 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: Suzhou, Jiangsu Province, China

- Contact Person: Mr. Jason Chang

- Tel: +886-912-195558

Premium Related Products

Other Products

Hot Products

New Building Material Threaded Rod Splicing Steel Rebar CouplerSteelwork Fixing Beam ClampHot Sale Wheel Hub Cover Caps for NissanABS Plastic Hub Rings for Wheel Spacers & AdaptersDacromet Plated Expansion Anchor BoltHex Torx Ball End Allen Wrench Spanner Set1/2 to 3/8 Inch Socket Adaptor Driver for Mechanic RepairPhillips Hex Slotted Torx Bit Socket6 Point 1/4"Drive Shallow Socket with Matt/Mirror FinishedMirror Surface Polishing Cr-V 1/2" 3/8"Spark Plug Sockets1/4"--7/8" Adjustable Ratchet Socket Wrench of Repair Tools4PCS Aluminium Car Tyre Valve Stem Set6PCS Hex Wheel Lug Bolt with Chrome Surface4+1PCS Hardened Steel Wheel Lug Bolt218PCS Cr-V Household Socket Set for Hand ToolsHigh Security Aluminum Wheel Lock Nut